running compression test waveform|Engine Compression Tests : factories With a relative compression test, you can easily determine if all the cylinders in an engine have equal compression. This test is a quick check on compression that you can do without removing the spark plugs or glow plugs. Resultado da DFranquias ERP / PDV. Ambiente gerencial e ponto de venda. ENTRAR. Projetamos na necessidade de ser diferente. Whatsapp. Suporte. .

{plog:ftitle_list}

webClimatempo é um site de meteorologia que oferece informações sobre o clima e a previsão do tempo em todo o Brasil. Veja as condições atuais, a tendência para o carnaval 2024 e .

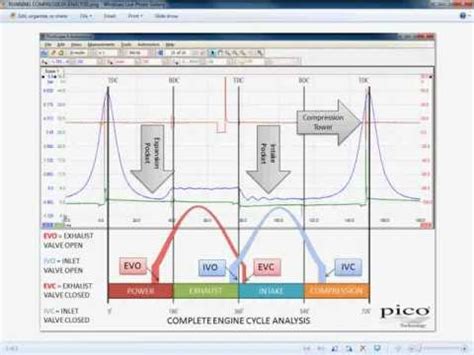

Running a compression test or dynamic compression test is an important, but little-used and often overlooked engine diagnostic tool. Why is this test so significant? It can be used to . Understanding these waveforms will help you spot valve issues, blocked catalytic converters and restricted air intakes. First Uploaded on Jan 19, 2012Viewing the pressure . Firstly, a running dynamic compression test, confirms how effective each cylinder is, at pulling air in. Secondly, holding it for the correct .

Viewing the pressure waveforms from inside the cylinder of a running engine can provide a great deal of diagnostic information. Understanding these waveform.

With a relative compression test, you can easily determine if all the cylinders in an engine have equal compression. This test is a quick check on compression that you can do without removing the spark plugs or glow plugs.This waveform can convey such things to the technician as; true Top Dead Center (TDC), camshaft timing, ignition timing, restricted exhaust, intake valve problems, exhaust valve problems, and piston sealing problems in just seconds.pressure waveforms are comprised of. This means that each time the throttle valve is changed the pressure within the cylinder also changes. The three basic throttle pressure states that will .

The Compression test within our PicoDiagnostics software (bundled with PicoScope 7 Automotive) reveals engine mechanical issues by calculating relative compression values for each of your engine’s cylinders. The .An in-depth analysis of a compression test using a PicoScope with a WPS500X pressure sensor to record pressure over the entire four-stroke cycle whilst the engine is running to highlight faults and problems. Running Compression – The running compression test is done by starting the engine with a professional-grade compression gauge installed in the cylinder. While we’re not looking for specific numbers, let’s say .Anatomy of the Compression Waveform by Bernie Thompson – ATS. . When this running pressure drops below 40psi a misfire will occur. This is an indication that the pressure within the cylinder is no longer adequate to support the .

In June 2013 the article “Introduction to in-cylinder pressure testing” covered the running idle compression waveform. In May 2014 “Introduction to in-cylinder pressure testing part II” covered the cranking compression waveform. .

Understanding running compression waveforms

Anatomy of the Compression Waveform by Bernie Thompson – ATS. . When this running pressure drops below 40psi a misfire will occur. This is an indication that the pressure within the cylinder is no longer adequate to support the combustion of the hydrocarbon chains. . During a snap throttle compression test the idle compression pressure .Waveform Buffer. This allows you to scroll through frames of data post-test and to review your waveform captures. Zooming in on the camshaft waveform, it soon became clear there was an intermittent fault. Running the test again, while gently wiggling the wiring loom, it quickly became apparent that there was a wiring issue.

Fully Automatic Bottle Cap Torque Tester commercial

If a relative compression waveform highlights a problem, it will be necessary to perform a compression test. When compression testing on a petrol engine, it is important to fully open the throttle to allow a larger quantity of air to pass into the cylinders. A typical compression is between 120 and 200 psi. A low compression can be caused by:In reality, there will be some slight variation. Any repetitive low peak in the waveform indicates a cylinder with low compression and provides justification for further investigation. Compression related issues can cause poor running, misfire and emissions related symptoms. Typical faults that cause compression issues are:Run this test to find out. 1-800-761-3041 Contact Account Cart Search Waveform.com. Cancel Close Menu. External Antennas. For Gateways/Routers. Cell Boosters. For Buildings & Vehicles. For Large Buildings. Over 15k Sq Ft. By Carrier. Accessories. Guides & Tools. Account; Returns .

The engine is then started and allowed to idle. The in-cylinder running pressure waveform taken from cylinder #8 is shown in Figure 1. This waveform clearly shows a problem. This problem can be seen by comparing it to an in-cylinder compression waveform taken from good cylinder #6, as seen in Figure 2. Let’s look at problem cylinder #8 in .Service Procedure for Running a Compression Test A technician may find that a relative compression test can be used to rule out an engine compression issue. A . Waveform Buffer Index navigation buttons to locate the start of the cranking. 5419756 The graphic above depicts a viewable Wave FormIn reality, there will be some slight variation. Any repetitive low peak in the waveform indicates a cylinder with low compression and provides justification for further investigation. Compression related issues can cause poor running, misfire and emissions related symptoms. Typical faults that cause compression issues are:

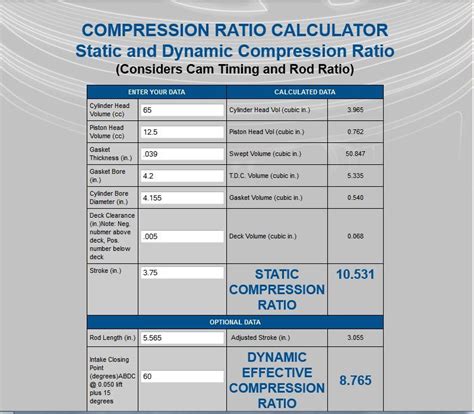

Static Vs Dynamic Compression Ratio

The engine is then started and allowed to idle. The in-cylinder running pressure waveform taken from cylinder No. 8 is shown in Figure 1. Fig 1. This waveform clearly shows a problem, which can be seen by comparing it to an in-cylinder compression waveform taken from good cylinder No. 6, as seen in Figure 2.In this test we will use the WPS500X Pressure Sensor to graph the pressure of the cylinder whilst the engine is running. Software: PicoScope 6 - Guided Test AT157; Purpose of Test - Petrol Engine Compression . Once you have captured your cylinder compression test waveform you will be able to see everything that is taking place in every 720 .

The purpose of the test is to check the relative compression of the cylinders within a hybrid vehicle's Internal Combustion Engine (ICE) using changes in cranking speed calculated from a Crankshaft Position (CKP) sensor signal. . the calculated engine speed is approximately 840 RPM, giving the impression that the engine is running at idle .In this Compression Test animation, an exhaust valve on Cylinder 1 is not sealing properly (valve-stem bent). . Run: Crank the engine. . the ignition pulse occurs at cylinder 1 and therefore the cylinder with low compression is .

A Running Compression test with a compression gauge is checking individual cylinder breathing. With the engine running, I prefer leaving the Schrader valve in the tester and “Burping” the gauge after a few seconds of running. The .

Let us start by analyzing the idle compression waveform as seen in figures 1 and 2. Figure 1 is a camshaft chart with the compression waveform overlaid on the cam card. Figure 2 is a basic compression waveform produced at closed . The relative compression waveform in blue shows a single cylinder that has low or no compression (figure 1). The green trace is cranking vacuum waveform obtained using a piezoelectric sensor attached to the intake manifold at the PCV valve hose. An obvious mechanical failure is also evident in the vacuum waveform.

In the images of the cranking compression test, there is some good information. Note the waveform pressure readings on all the cylinders. The pressure (positive voltage on cylinders No. 1, No. 2 and No. 3) are all very similar at approximately 50 psi. The voltage on cylinder No. 4 is significantly higher (approximately 120 psi).In June 2013 the article “Introduction to in-cylinder pressure testing” covered the running idle compression waveform. In May 2014 “Introduction to in-cylinder pressure testing part II” covered the cranking compression waveform. Cylinder pressure testing is becoming one of the most important new diagnostic tools for a shop to use. This .

Running Compression – The running compression test is done by starting the engine with a professional-grade compression gauge installed in the cylinder. While we’re not looking for specific numbers, let’s say that running compression at idle for an average engine is roughly 80-90 psi. . Photo4: A pressure wave transducer doesn’t .

Running Dynamic Compression Test – How To Do It

This tutorial help you to test the engine compression on your Ford F-150, F250, and F-350 pickups. . If the engine has been running for any length of time, let it cool down before removing the spark plugs. Removing the spark plugs from a hot engine can cause the spark plug hole threads to strip in the cylinder head. This is a nightmare you . Viewing the pressure waveforms from inside the cylinder of a running engine can provide a great deal of diagnostic information. Understanding these waveforms.

When analyzing the in-cylinder waveform several things stand out, such as the leaning compression towers, and the deep exhaust pocket. These items clearly show the cylinder is leaking. Now look at the intake waveform in blue. The cylinder intake pull marked 1 is from the cylinder we are currently testing.Waveform features. When captured during a snap throttle test, the relationship between the in-cylinder pressure waveform features and engine events can be described in turn, as follows: Each pressure pulse peak occurs at peak compression during the compression stroke. Therefore, the peaks are separated by 720° of crankshaft rotation.

Earlier, I published the “Introduction to In-cylinder Pressure Testing Part I” covering the running idle compression waveform. That was followed by "Introduction to In-cylinder Pressure Testing Part II" covering the cranking compression waveform. Cylinder pressure testing is becoming one of the most important new diagnostic tools for a shop to use. This technique provides .

As a minimally invasive test, I would be interested in seeing intake and exhaust pulse waveforms, added to the RC waveform. Since it becomes a bank-to-bank issue when warm, and you have had one head replaced, I would capture a running compression waveform from one cylinder, on each bank, when the engine is cold.

Bottle Wall Thickness Tester commercial

Hall Effect Thickness Gauge (Bottle Thickness Tester) commercial

webSpecial wind and weather forecasts for windsurfing, kitesurfing and other wind related sports. Forecasts for any location on planet Earth!

running compression test waveform|Engine Compression Tests